Product Introduction

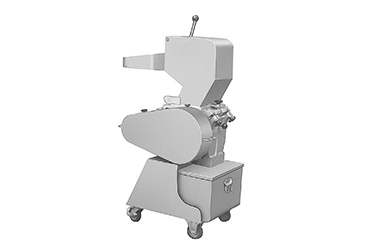

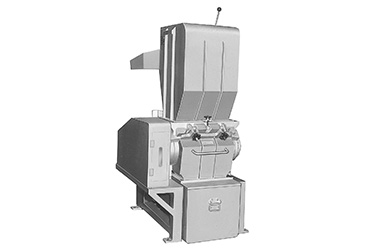

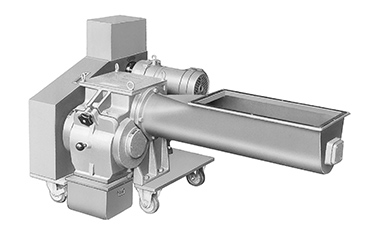

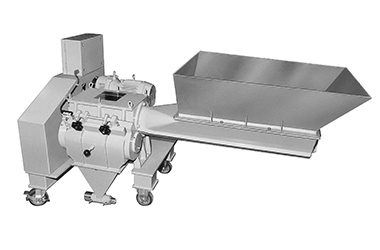

V-Series

Pulverizers for injection, extrusion, and blow molded products

Fast, powerful pulverizing for large molded items and runners

Characteristic

The combination of a unique J-shaped wall surface and the most effective cutting point, and a large-diameter input port provide excellent biting performance. Crush big volume molded products and runners at once.

Thorough pursuit of crushing characteristics such as light and bulky molded products and runners. A clean crushed product with a short residence time in the crushing chamber, a large processing capacity, and few "powder", "fine particles", and "whiskers" can be obtained.

A bolt set type blade is used for the rotary blade. Since it is a high-efficiency machine with low spare blade and blade grinding costs and good biting properties, it boasts low power consumption per processing amount and high economic efficiency.

A sandwich-structured steel plate with a special plastic as an intermediate layer is used to reduce noise.

High-frequency sound is also minimized, and pollution prevention is effective for mental hygiene.

Series lineup

| Model name | V-210 |

|---|---|

| Motor | 4P 2.2kW |

| Unit dimensions | 510mm(W) 785mm(L) 1,455mm(H) |

| Unit weight | 260kg |

| Model name | V-360 |

|---|---|

| Motor | 4P 3.7kW |

| Unit dimensions | 780mm(W) 960mm(L) 1,530mm(H) |

| Unit weight | 430kg |

| Model name | V-420 |

|---|---|

| Motor | 4P 11kW |

| Unit dimensions | 1,020mm(W) 1,165mm(L) 1,850mm(H) |

| Unit weight | 700kg |

| Model name | V-480 |

|---|---|

| Motor | 4P 15kW |

| Unit dimensions | 1,120mm(W) 1,385mm(L) 2,330mm(H) |

| Unit weight | 1,250kg |

| Model name | VS-210 |

|---|---|

| Motor | 4P 2.2kW |

| Unit dimensions | 1,400mm(W) 845mm(L) 900mm(H) |

| Unit weight | 350kg |

| Model name | VS-360 |

|---|---|

| Motor | 4P 3.7kW |

| Unit dimensions | 1,580mm(W) 860mm(L) 970mm(H) |

| Unit weight | 600kg |

Pulverization sample

Runners

Blow molded products